tooltechenq@gmail.com View Mobile Number

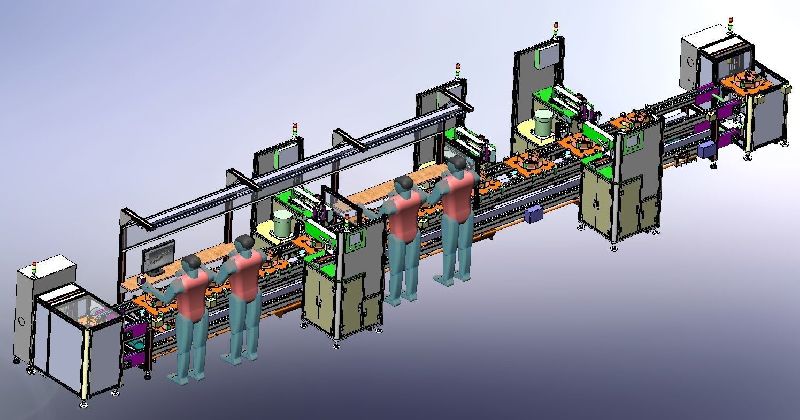

As a result of ever changing technology, more and more assembly lines are being automated. In order for an assembly line to be completely automated it requires the use of robots that perform tasks that would otherwise be done by people. If you were to see one in operation you may notice some things.

The first thing you might notice is a group of workers standing close together. These workers will typically monitor and ensure proper operations of the fully automated assembly line. They make sure the robot equipment is working properly and fix any malfunctions.

You may also see a conveyor belt moving items from station to station within the factory floor. This conveyor belt has no person directing its movements; instead, there is machine guidance and collision detection.

Human workers are only required during final assembly and packaging stages. Before those steps begin, robots perform all functions related to welding, painting and car-body assembly as well as automated sorting and storage systems for parts storage.

One of the main benefits is that they require less time to set up. Another benefit is that there are fewer errors made when working on an automated assembly line. Lastly, since many products have different sizes and shapes, humans would have more difficulty trying to figure out where each piece goes if it was an irregular shape or size